As shown in the schematic, the system uses a patented design consisting of an Attenuated Total Reflection (ATR) sample plate with an electronically modulated source on one end. At the other end of the ATR window is a linear variable filter (LVF) covering a wavelength range of 5.4-10.8 μm (1850-925 cm-1) combined with a 128 pixel detector array. The result is an infrared analyzer that, unlike an FTIR spectrometer, has no moving parts and an insignificant optical air path. This makes for a portable, rugged analyzer suitable for use in a production or field environment. The InfraSpec VFA-IR Spectrometer has a simplified PC interface for non-technically trained personnel as well as complete data and spectral information that can be transmitted to laboratory technicians for review if necessary.

Compliance with ASTM D7861:

The ASTM method D7861 was written in order to give fuel terminals/distributors and regulatory agencies a field test method for measuring biodiesel in diesel. The InfraSpec VFA-IR Spectrometer fully complies with ASTM D7861 and was the primary instrument used to develop the precision statement for the method. There were a total of 27 independently developed samples of varying biodiesel content (1 – 30%) measured on each of twelve spectrometers. The samples contained one of three types of biodiesel (soy, canola, waste vegetable oil) and one of three diesel fuels which differed in aromatic content. The samples were run three times on each instrument and the results sent to an independent, statistician for analysis. The calculated repeatability and reproducibility compared favorably with that of D7371. Differences in the biodiesel type or diesel type had no significant effect on the calculated repeatability and reproducibility. Also, the data showed no significant differences in accuracy between biodiesel types.

Comparison to D7371 and EN14078:

Each sample was measured by an independent laboratory using an FTIR for ASTM D7371 and EN14078 and the InfraSpec VFA-IR Spectrometer. The results from the Infra-Spec VFA-IR Spectrometer show a good correlation to the two FTIR methods with an r2 greater than 0.999.

Conclusion:

The InfraSpec VFA-IR Spectrometer is an easy-to-use, rugged, and portable solution for the measurement of biodiesel in diesel. Repeatable results can be obtained in under a minute making the InfraSpec the ideal instrument for on-site measurements. Compliance with ASTM D7861 and high correlation to ASTM D7371 and EN 14078 make the InfraSpec an excellent alternative to more expensive FTIRs.

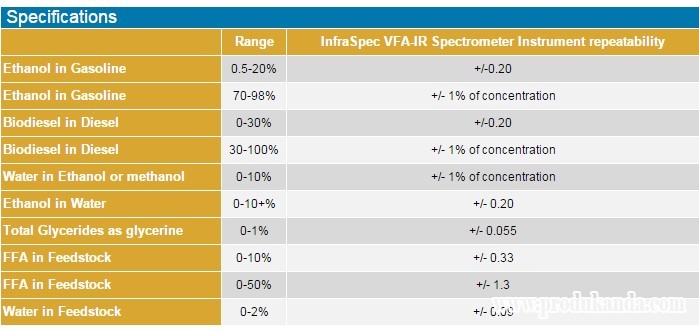

Measures:

- Biodiesel in diesel fuel

- Ethanol in gasoline

- Water in ethanol/methanol

- FFA in Oil/Feedstock

- Water in feedstock

Features & Benefits

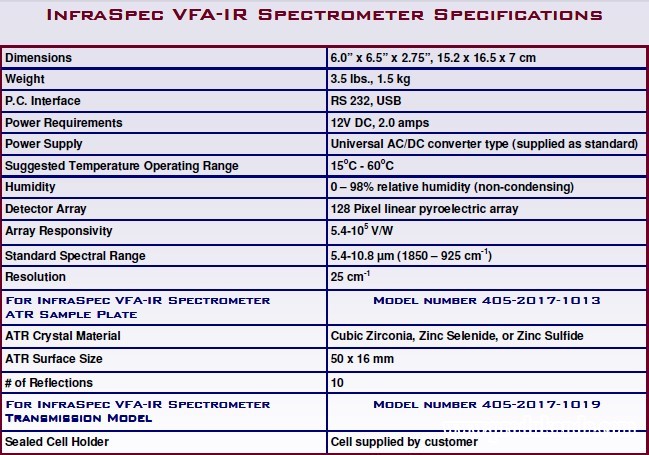

Specifications:

Highlights

The InfraSpec VFA-IR Spectrometer can be ordered with or without factory calibration. Biodiesel in Diesel Factory calibration available 0 – 100% Biodiesel in Diesel percent measurement. The calibration range includes ten points; 0, 2, 5, 10, 15, 20, 25, 30, 50, 75, 95 &100%. The calibration is performed using biodiesel in High Cetane diesel fuel prepared by a certified laboratory.

For Ethanol in Gasoline there are two ranges of calibration available are 0-20% and 70-100%. A 0-20% 5 Point Ethanol Low Concentration Calibration includes 0, 5, 10, 15, and 20% ethanol in gasoline points. A 70-100% 5 Point Ethanol High Concentration Calibration includes 70, 80, 90, 95, and 100% ethanol in gasoline. The calibration is performed using standards prepared by a certified laboratory.