Universal Oven UN160plus

Standard delivery Universal Oven

The universally applicable lab oven U is Memmert’s classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology.

On this page, you can find all the essential technical data on the universal Memmert lab oven. Our customer relations team will be pleased to help if you want further information. If you should require a customised special solution, please contact our technical specialists at myAtmoSAFE@memmert.com.

Properties

Control of standard components

| Temperature | 2 Pt100 sensors Class A in 4-wire-circuit, mutually monitoring and taking over the performance at the same temperature value |

|---|---|

| ControlCOCKPIT | adaptive multifunctional digital PID-microprocessor controller with 2 high-definition TFT-colour displays |

| Timer | Digital backwards counter with target time setting, adjustable from 1 minute to 99 days |

Temperature

| Set temperature range in °C | min. 5°C above ambient up to +300°C |

|---|---|

| resolution of display for setpoint values 0.1°C up to 99.9°C, 0.5°C from 100°C and for actual values 0.1°C (LED) | |

Control technology

| Function HeatBALANCE | adapting the distribution of the heating performance of the upper and lower heating circuit from -50 % to +50 % |

|---|---|

| Function SetpointWAIT | the process time does not start until the set temperature is reached |

| Language setting | German/English/Spanish/French |

| Calibration | three freely selectable temperature values |

| adjustable parameters | temperature (Celsius or Fahrenheit), air flap position, programme time, time zones, summertime/wintertime |

Ventilation

| natural convection | |

|---|---|

| Fresh air admixture | adjustment of pre-heated fresh air admixture by air flap control in 10 % steps for each segment individually |

| Vent | vent connection with restrictor flap |

Communication

| Documentation | programme stored in case of power failure |

|---|---|

| Programming | AtmoCONTROL software on a USB stick for programming, managing and transferring programmes via Ethernet interface or USB port |

Safety

| Temperature control | mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature |

|---|---|

| Temperature control | overtemperature monitor TWW, protection class 3.1 or adjustable temperature limiter TWB, protection class 2, selectable on display |

| AutoSAFETY | additionally integrated over- and undertemperature monitor "ASF", automatically following the setpoint value at a preset tolerance range, alarm in case of over- or undertemperature, heating is switched off in case of overtemperature |

| Autodiagnostic system | for fault analysis |

| Alarm | visual and acoustic |

Standard equipment

| Scope of delivery | incl. works calibration certificate for +160°C |

|---|---|

| Door | fully insulated stainless steel door with 2-point locking (compression door lock) |

| Housing | rear zinc-plated steel |

| Interior | easy-to-clean interior,made of stainless steel,reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides |

| Internals | 2 stainless steel grids |

Stainless steel interior

| Max. loading of chamber: 210 kg | |

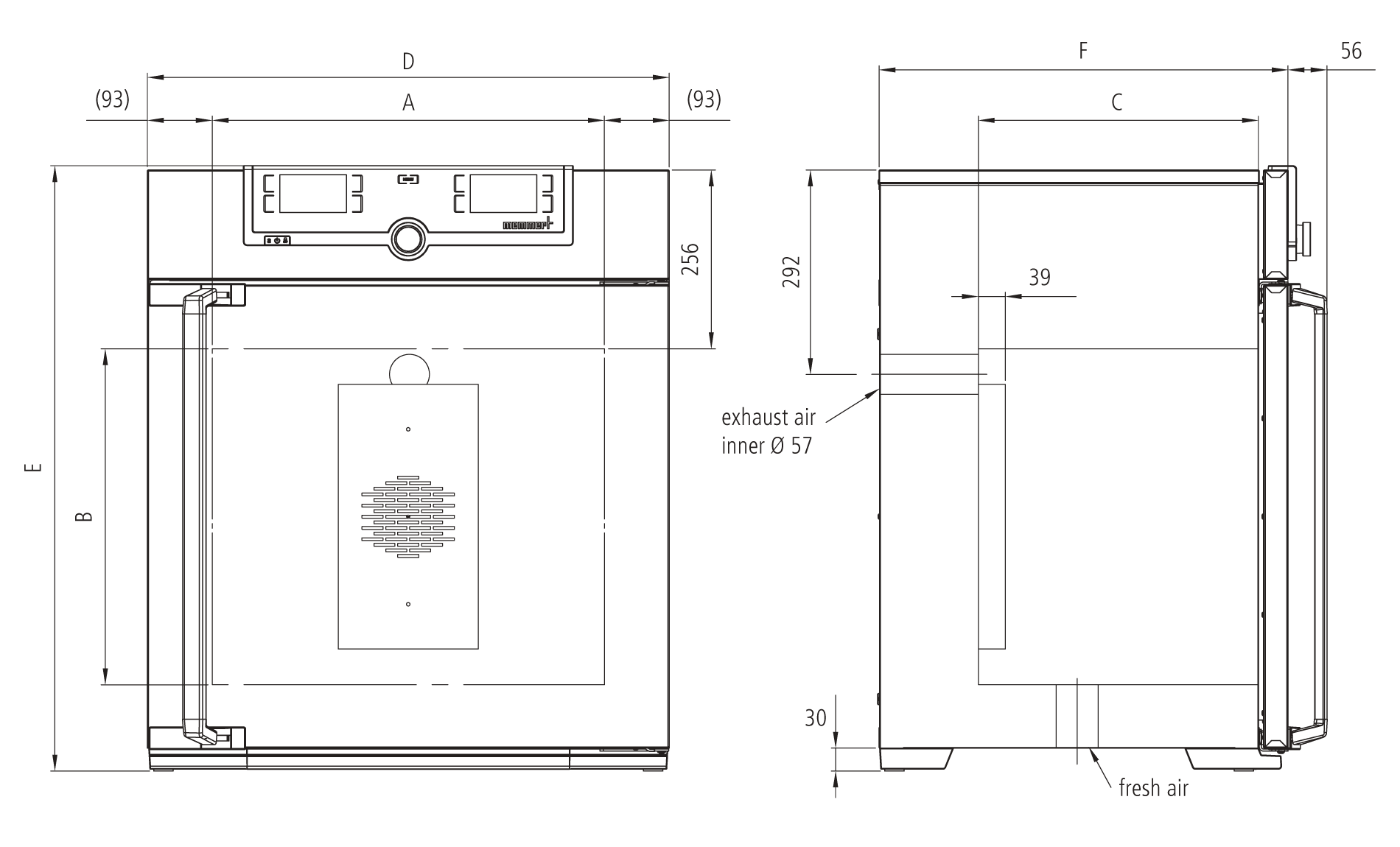

| Dimensions W x H x D in mm | w(A) x h(B) x d(C): 560 x 720 x 400 mm |

|---|---|

| Volume 161 l | |

Textured stainless steel casing

| w(D) x h(E) x d(F): 745 x 1104 x 584 mm |

Electrical data

| Voltage Electrical load | 230 V, 50/60 Hz approx. 3200 W |

|---|---|

| Voltage Electrical load | 115 V, 50/60 Hz approx. 1800 W |

Packing/shipping data

| the appliances must be transported upright | |

|---|---|

| Customs tariff number | 8419 8998 |

| Country of origin | Federal Republic of Germany |

| WEEE-Reg.-No. | DE 66812464 |

| Dimensions approx incl. carton B x H x T: 830 x 1300 x 800 mm | |

| Net weight approx. 96 kg | |

| Gross weight carton approx. 122 kg | |